Pierce NN-1 Tieback

Client: Shell UK Limited

Tieback of Pierce NN-1 well to the Pierce Field GLM. Flow assurance and pipeline engineering performed to assist Shell in producing level 3 cost estimates.

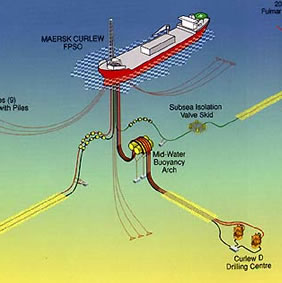

Curlew-C Transient Gas Lift Study and Blowdown

Client: Shell E&P (UK)

Study examined the blowdown procedure for the Curlew-C gas-lift line and riser to determine minimum temperatures relative to pipe minimum design temperature.

Curlew-C Transient Flow Assurance Study

Client: Shell E&P (UK)

Performed detailed shutdown, blowdown production start-up studies to inform the system operating procedures subject to facilities capacity, piping constraints and methanol injection constraints.

Penguins Development

Client: Shell E&P (UK)

Study was performed to evaluate the impact of the new

developments (infill wells) on the hydrodynamic stability of the Shell

Penguins gas field. Study also involved a complete flow assurance

analysis and system operability review.

Penguins Landed Pressure reduction Study – Study to evaluate the impact

of landed pressure reduction of the Penguins field on fluid

characteristics (slugging) and pipe erosional limit.

Tsiengui-Coucal Pipeline Assessment

Client: Shell (Gabon)

Performed pipeline simulation study to evaluate the pipeline hydraulic capacity and operating envelop subject to minimum temperature constraints resulting from relatively high fluid pour point temperature, wax formation, pipeline design pressure limits and erosional velocity constraints.

H-Block Development – Flow Assurance Study

Client: Shell (SPDC, Nigeria)

Job comprised hydrodynamic stability and pigging

studies for the HA NAG pipeline, HD export line study - line sizing of

export line from central production hub to offshore gas gathering system

with line size optimisation based on hydraulic capacity and erosional

velocity constraints;

JK Oil multiphase export line study - hydraulic capacity study to verify

proposed line size; slugging study.